Latham Pools' 8 - Stage manufacturing process ensures that your pool is built to the highest industry standards

Latham’s Advanced Composite Technology was developed with intensive research and testing, making Latham fiberglass pools easier to handle and install. Latham fiberglass is stronger, more ridged and more durable. It is built better and backed better, with the best warranties in the industry.

- Crystite Gelcoat – Engineered and built for fade, stain and scratch resistance, our gelcoat has been offering the industry’s most beautiful and durable swimming pool surface in it most popular colors for over 25 years. And now you can enjoy the radiance of our exclusive G3 finishes, adding and extra sparkle to your pool.

- Vinyl Ester Resin – Our resins are designed for corrosion and impact resistance, flexibility, strength, and durability.

- Advanced Ceramic Construction – Ceramic – infused resin provides increased stiffness

- BiMax Radius Reinforcement – The tight weave and direction of the fibers within this material add tremendous strength to the pool shell.

- Carbon Infused Technology – Carbon fiberglass have the highest quality compressive strength of all reinforcing material, and are found in automobiles, boats, yachts, airplanes, and spaceships.

- Dupont Kevlar Aramid Fibers – Developed for demanding industrial and advanced – technology application, Kevlar combines high strength, toughness and thermal stability.

- Woven Roving and Marine – Grade Resin – Woven roving dramatically reinforces the strength of the pool shell.

- Closed Beam Construction – Our unique closed beam construction creates unparalleled strength and rigidity.

fiberglass pools

Ready to build a fiberglass pool in central Indiana? Perma Pools is here to help! Fiberglass pools are quick to install and typically run up to 16 feet wide and 40 feet long.

vinyl liner pools

Perma Pools is ready to help you save money on your brand new pool! Our vinyl liner pools are a great budget-friendly option and are highly customizable.

Pool services

Our certified pool technicians are ready to bring your pool to life! We work year-round to service your pool and keep it well maintained for years of fun!

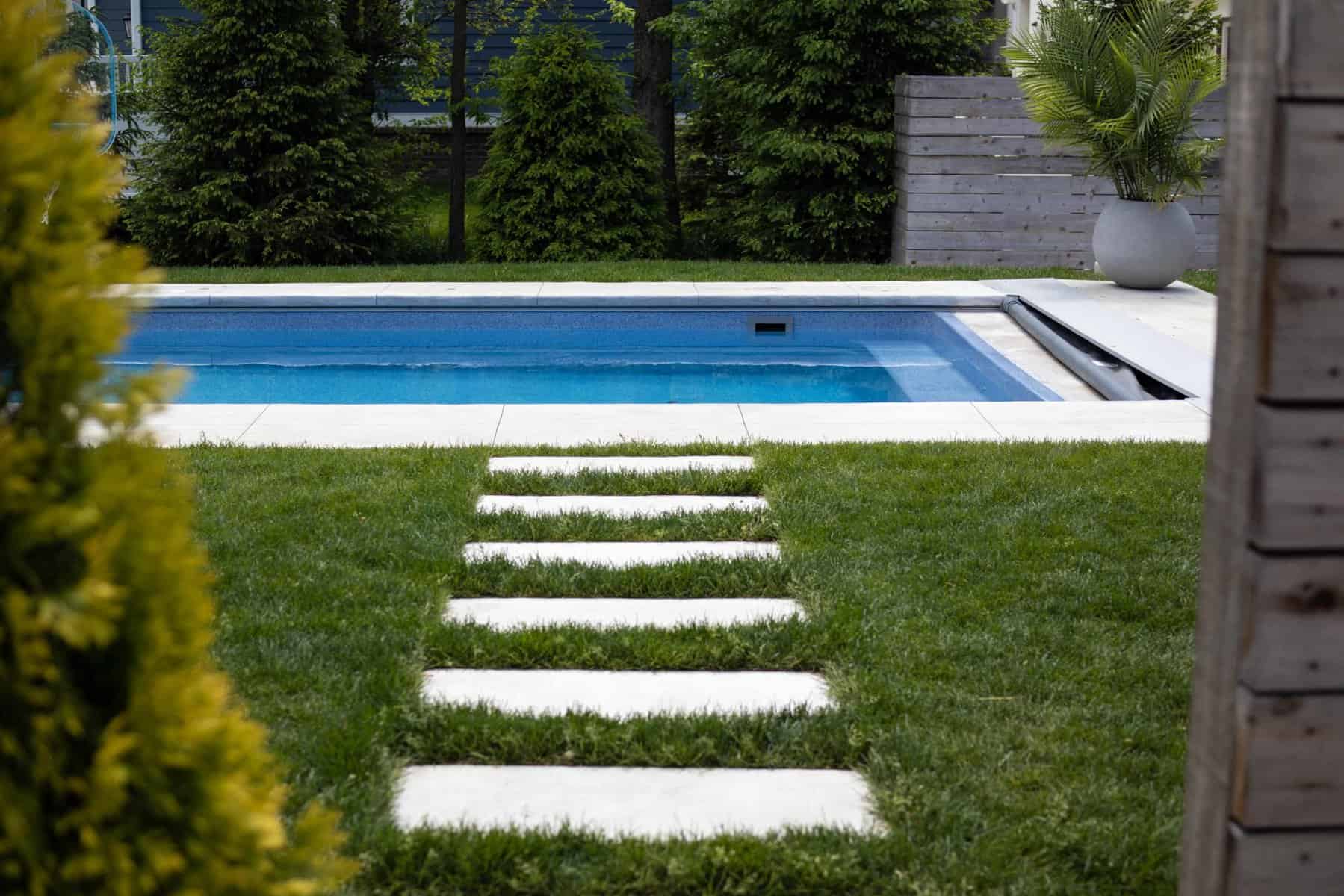

Automatic Pool Covers

Perma Cover Services offers sales and installation of fully automatic deck mounted and recessed retro automatic pool cover systems.